FIRE ALARM SYSTEM

A properly designed, installed, operated, and maintained fire alarm system can reduce the losses associated with an unwanted fire in any building. These losses include property and, more importantly, human life. The primary motivation for fire alarm system requirements in building and fire codes is to provide early notification to building occupants so they can exit the building, and to notify the fire service so it can respond to the fire. In settings such as hospitals the fire alarm system provides notification to staff so they can respond to the fire emergency (as opposed to evacuating the building). This module will explain the basic features of fire alarm systems and the inspection of these systems. It should be noted that fire alarm systems also are called “protective signaling systems,” especially in NFPA documents and in other codes and standards.

Basic Components of a Fire Alarm System

- Alarm Initiating Device Circuits

These are the circuits which connect initiating devices such as smoke detectors, heat detectors, manual pull stations, and water flow alarms. Additionally, many system monitor devices important to the overall fire safety of the building also tie in to initiating circuits. These devices indicate an “abnormal” condition, not a fire or “alarm” condition. They are referred to as “supervisory devices.” One example would be the valve supervisory switch or tamper switch of a valve controlling the automatic sprinkler system. These types of devices also may be connected to supervisory type circuits.

- Fire Alarm Control Panel

The fire alarm control panel contains the electronics that supervise and monitor the fire alarm system. The initiating and indicating circuits are connected directly into this panel.

- Alarm Indicating Appliance Circuits

Audible and visible alarm indicating appliances tie in to these circuits to provide warning to the building occupants. Devices which send a signal off premises also can be connected to these circuits.

- Primary Power Supply

The primary electrical supply powers the entire fire alarm system. Primary power for fire alarm systems typically is provided by connecting into the local commercial power service.

- Secondary Power Supply

A separate power supply that will operate automatically when the primary power fails and is capable of operating the entire system is considered a secondary power supply.

Initiating Devices

Initiating devices fall into one of two main categories: either those that indicate an alarm condition, or those that indicate an abnormal condition of a monitored device. A brief description of the common types of devices follows.

Fire detection can occur by using any device that responds to conditions caused by fire. The most common byproducts of fire are heat, smoke, flames, and fire gases.

In addition, people can detect a fire and initiate an alarm by activating a manual pull station. Also, when a sprinkler system activates and causes an alarm, it is a result of the sprinkler system detecting heat produced by the fire (if the sprinklers have fusible links).

- Heat Detectors

Heat detectors commonly are used to detect fires. They are not as prone to false alarms and are less expensive than smoke detectors. However, the response of heat detectors may not be adequate in many instances, which limits their usefulness. Heat detectors are slower to respond to fires than are smoke detectors because heat detectors cannot respond to smoke. Heat detectors typically are best suited for detecting fast-growing fires in small spaces. Heat detectors are also a means of fire detection in locations that smoke detectors cannot protect due to such environmental effects as mist, normally occurring smoke, and high humidity. Heat detectors have several different operating mechanisms.

Fusible-element type mechanisms use a eutectic alloy that melts rapidly at a predetermined fixed temperature. When this temperature is reached and the fusible alloy melts, an electrical contact occurs and causes an alarm. Fusible alloys also are commonly used in sprinkler heads. These mechanisms must be replaced after each operation.

Bimetallic type mechanisms combine two metals with different thermal expansion coefficients. As the mechanism heats, one metal expands more than the other, causing a deflection in the shape of the element. This deflection causes an electrical contact, thus initiating an alarm. These types of mechanisms are self-resetting as the element cools.

Rate-compensated heat detectors respond to a given temperature of the surrounding air regardless of the rate at which the temperature rises. This, in effect, compensates for thermal lag, which standard thermal detectors do not do. This can be compared to the rate-of-rise detectors discussed immediately below.

Some heat detectors operate on what is commonly referred to as the “rate of rise” principle. Regardless of the ambient temperature, if the detector senses a rise in temperature exceeding a set amount, an alarm occurs. One method of accomplishing this is using a container that has a small vent hole. As air is heated it expands; this can cause a set of contacts to close and send an alarm. If the expanding air can leak out of a vent hole, the resulting pressure will be reduced. However, if the air expands at a rate faster than the vent hole can compensate for, the contacts will close and an alarm will be sent.

- Combination heat detectors can combine the two operating principles of reaching a fixed temperature and reaching a set rate of rise. Smoke and heat detectors also can be combined into a single unit. It should be noted that some combination smoke/heat detectors activate when either condition is reached, while others require both the smoke and heat mechanisms to operate. In most cases, little benefit, if any, results from the combination detector which requires both heat and smoke to cause an alarm.

- Other types of heat detectors include heat-sensitive cables and liquid expansion detectors.

- Smoke Detectors

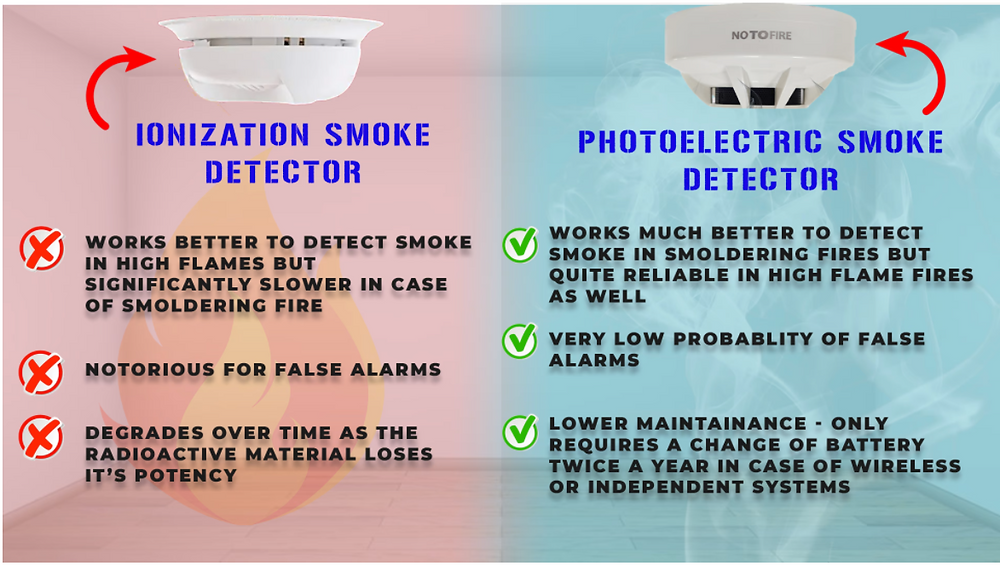

One cannot overemphasize the benefits of smoke detectors. However, smoke detectors are not usable in all environments and their effectiveness varies depending on the fire scenario and occupant capability. The two basic operating mechanisms currently used in smoke detectors are photoelectric and ionization.

- Ionization smoke detectors

- Photoelectric smoke detectors

have a small amount of a radioactive material located within the detector that “ionizes” the air entering the detection chamber. Once ionized, the air particles become conductive, allowing a current to flow through the detector circuitry. Smoke entering the ionization chamber causes a reduction in the current flowing through the detector’s circuitry. At a certain reduced level of current flow, the detector signals an alarm.

use one of two methods to detect smoke; however, both use a light-emitting source and a receiver. Photoelectric smoke detectors that operate on the “light obscuration” principle work as follows. A light source is directed at a receiver which is accustomed to receiving a certain intensity of light. When smoke particles enter the detection chamber they partially block the light traveling from the emitter to the receiver. When the light is reduced or obscured by a certain amount, the detector’s built-in circuitry sounds an alarm.

The second operating principle used in photoelectric detectors is that of “light scattering.” It is more common and operates as follows. The receiver in the detection chamber is located so that the light emitted is normally not “seen” by the receiver. That is, the light emitter and receiver are not aligned as with the light obscuration method. When smoke enters the detection chamber, light from the emitter strikes it. A fraction of the light striking the smoke particles is scattered or “reflected” away from the smoke particle. Some of this scattered light lands on, or strikes, the photo receiver. When a preset amount of light lands on the receiver, the detector signals an alarm.

Detectors that operate on the photoelectric principle are generally appropriate in locations where slow-growing, smoldering fires are expected. These fires typically generate large size particles (0.3-10 microns). They also respond better to light gray smoke as opposed to very dark smoke. Ionization-type detectors respond better to fast-flowing, flaming fires that produce smaller particles (0.01-3.0 microns). Ionization detectors respond better to dark smoke than to light smoke. Photoelectric detectors are better suited than ionization detectors for locations with high humidity. Air velocity also may affect smoke detector operation.

A special type of photoelectric smoke detector is the projected-beam detector. Here the operating principle is the same as a light-obscuration- based detector but the light emitter and the receiver are physically separated across large areas (e.g., the length of a room). Smoke at any location between the two components can result in an alarm. These detectors also can be used in conjunction with mirror systems so that the projected beam is directed in several directions before ultimately striking the receiver.

Another special type of smoke detector is the cloud chamber smoke detector. This detection system uses a pump to sample the air from a given room. The air is pumped into a high humidity chamber and the pressure in the chamber then is reduced slightly. If smoke particles are present, as the pressure is lowered, moisture will condense on the smoke particles. This creates a “cloud” within the chamber. The photoelectric principle discussed above is then used to detect the presence of the “cloud” and, hence, smoke.

Recent data indicate that health care facilities, for example, are experiencing an average of approximately 15 unwanted alarms for every real alarm. One problem resulting from these high averages is that people may ignore the fire alarm’s warnings during fire drills and actual emergencies, believing it to be “just another false alarm.” Quite obviously this could lead to a tragedy. Many of the unwanted alarms are attributed to “field” problems such as insects in the detector and other maintenance deficiencies.

Some modifications in detector design are helping to reduce the unwanted alarm problem. Alarm verification recently was approved by U/L. This allows the fire alarm panel to “wait” for a specified time period to see whether the signal from the detector is just from a brief exposure to smoke or from electrical “noise.” Device manufacturers are modifying their products continually to reduce the unwanted alarm rate. System maintenance can have a profound effect on the false alarms at facilities.

There are other ways to deal with the unwanted alarm situation: proper system design, installation, and acceptance test procedures. For example, the specification could specify a certain sensitivity rating such as 2.5 percent or 3 percent which would eliminate detectors that are too sensitive. During the acceptance test one should verify the sensitivity of the detectors. Also, proper location of smoke detectors with respect to air diffusers will assist in reducing unwanted alarms. As a general rule of thumb, a detector should have a three-foot separation from a supply air diffuser.